Electric Wire Manufacturing in India | Powering the National Future

The electric wire industry in India plays a critical role in the development and infrastructure of the nation. From powering homes and offices to enabling industries to operate efficiently, electric wires are the backbone of modern electrical systems. With the rapid growth in urbanization, industrialization, and infrastructure development, the demand for high-quality electrical wires and cables has skyrocketed. In this blog, we will take a deep dive into the electric wire manufacturing industry in India, its importance, technological advancements, and what makes it such a crucial part of the nation's progress.

The Electric Wire Industry in India: An Overview

India's electric wire manufacturing industry is one of the most prominent in the world. The country is home to numerous manufacturers producing a wide variety of wires, including copper, aluminum, and fiber-optic cables. These wires are used across different sectors such as residential, commercial, industrial, and power distribution, among others. The industry has witnessed rapid expansion over the last few decades, with the government's initiatives like "Make in India" and "Smart Cities" further boosting the sector's growth.

India is one of the largest producers of electrical cables and wires, contributing significantly to the global market. The industry has seen an evolution in manufacturing techniques, moving from traditional methods to modern, state-of-the-art processes involving automation and precision engineering.

Key Factors Driving the Electric Wire Manufacturing Industry

1. Increasing Power Demand: With India's population growing rapidly, the demand for electricity has surged. The government's focus on rural electrification and the expansion of the power grid system has led to a constant increase in the demand for electric wires and cables. Electrical wires are essential for transmitting and distributing power, both for domestic and industrial use.

2. Infrastructure Development: The governmental thrust on infrastructure development, including roads, railways, metro systems, and buildings, has spurred the demand for quality electrical wires. With urbanization at an all-time high, the construction of smart cities, airports, and industrial corridors requires reliable electrical systems that can only be established using high-quality wires and cables.

3. Technological Advancements: The electric wire industry in India has seen substantial technological advancements, from the use of higher-quality materials to automation and innovative manufacturing processes. These improvements have not only increased the efficiency of the production process but also ensured that the wires manufactured are durable, safe, and meet international standards.

4. Government Policies and Initiatives: Government initiatives like "Make in India," "Digital India," and "Atmanirbhar Bharat" have provided a significant boost to the manufacturing sector in India, including the electric wire industry. With the rise in demand for electrical wires across various sectors, these policies have encouraged both domestic and international companies to invest in manufacturing plants and production facilities in the country.

5. Rising Industrialization: With India becoming a hub for industries such as automotive, steel, and manufacturing, the demand for electrical wires has been continuously increasing. Industries require specialized cables and wires for efficient operation, safety systems, and automation, driving the need for quality electrical products.

Types of Electric Wires Manufactured in India

Electric wires and cables are manufactured in various types to cater to different needs and applications. These include:

1. Power Cables: Power cables are used for transmitting and distributing electrical power across residential, commercial, and industrial sectors. They come in both low and high voltage ranges, depending on the application. These cables are typically made of copper or aluminum, with copper being the more commonly used material due to its superior conductivity.

2. Flexible Cables: Flexible cables are designed for use in environments where movement is required. They are widely used in machinery, home appliances, and other applications where cables need to move or bend without damaging the wire's structure. Flexible cables are highly durable and offer great flexibility, making them ideal for dynamic applications.

3. Control Cables: Control cables are used for controlling and regulating electrical systems in industrial equipment, machines, and plants. These cables are typically designed to handle low voltage and are used in applications where electrical control is required for the smooth operation of machines and automation systems.

4. Instrumentation Cables: Instrumentation cables are used for monitoring and controlling instruments, sensors, and devices in various industries such as oil and gas, chemical processing, and power generation. These cables are designed to carry signals with high precision and low interference, ensuring reliable performance even in harsh conditions.

5. Fiber Optic Cables: Fiber optic cables are used for high-speed data transmission and are becoming increasingly popular with the growing demand for faster internet services. These cables use light signals to transmit data, offering faster speeds, greater bandwidth, and more secure connections than traditional copper cables.

6. House Wiring Cables: House wiring cables are used to connect electrical appliances, lights, and outlets within a home or office building. These cables are generally insulated and come in various sizes depending on the load capacity.

The Role of Electric Wires in Industrial Growth

India industrial growth would not be possible without a robust electrical infrastructure. Electric wires are integral in ensuring the smooth functioning of industrial operations, from providing power to machinery to enabling communication systems. In industries like automotive, electronics, chemicals, and oil and gas, specialized cables and wires are used to ensure safety, reliability, and efficiency. Without the right wires and cables, production lines could face interruptions, safety hazards, and inefficiencies.

The rise in automation and smart systems in industries requires highly specialized cables that can handle complex data transmission and ensure smooth operations. Manufacturers across India are working towards producing wires that meet global standards, ensuring that industries have access to the highest quality electrical components.

Environmental Considerations in Electric Wire Manufacturing

As the world becomes more conscious of environmental concerns, the electric wire industry in India has also made strides to incorporate eco-friendly practices. Manufacturers are increasingly adopting sustainable materials such as recyclable copper, aluminum, and eco-friendly insulation materials. Furthermore, many manufacturers are focused on reducing energy consumption during the production process and ensuring that the waste generated during manufacturing is properly disposed of or recycled.

There is also growing interest in the development of cables that reduce electromagnetic interference (EMI) and are better for the environment, including cables with low halogen content and those that are fire-retardant.

Quality and Standards in Electric Wire Manufacturing

One of the critical factors in electric wire manufacturing is the quality of the product. Electrical wires must adhere to international and national standards to ensure that they are safe, durable, and reliable. In India, the Bureau of Indian Standards (BIS) plays a crucial role in setting quality standards for electric cables and wires. This ensures that manufacturers comply with the necessary guidelines and produce products that meet the needs of various industries while maintaining safety and performance standards.

Manufacturers across the country implement rigorous quality control measures, such as advanced testing techniques, to ensure that every product that leaves the factory is of the highest quality. The use of modern machinery, skilled labor, and advanced technologies helps guarantee that the electrical wires produced are durable and effective in their intended applications.

The Future of Electric Wire Manufacturing in India

As India continues its journey towards becoming a global manufacturing hub, the electric wire industry is poised for further growth. Key trends such as the rise in renewable energy sources, electric vehicles, and automation will drive the demand for advanced wiring systems. Electric vehicles, in particular, require specialized wiring for batteries, charging stations, and electric motors, which will open new avenues for wire manufacturers.

Additionally, as the government continues to focus on upgrading the country's infrastructure, including building smart cities, the demand for high-quality electrical wires and cables will remain strong. Innovations in technology, including AI-driven manufacturing processes and increased use of robotics, will continue to shape the future of the electric wire industry in India, making it more efficient and sustainable.

Conclusion

The electric wire manufacturing industry in India is essential to the country's infrastructure, development, and industrial growth. As demand for electricity, technological advancements, and industrialization continue to rise, the industry role will only become more critical. By providing essential components for power transmission and distribution, industrial operations, and communication systems, electrical wires ensure the smooth functioning of modern society.

As manufacturers embrace new technologies, improve product quality, and adhere to stringent environmental standards, the industry will continue to evolve and contribute to India economic growth. Through constant innovation and investment in the latest manufacturing processes, electric wire manufacturers are powering India towards a brighter, more sustainable future.

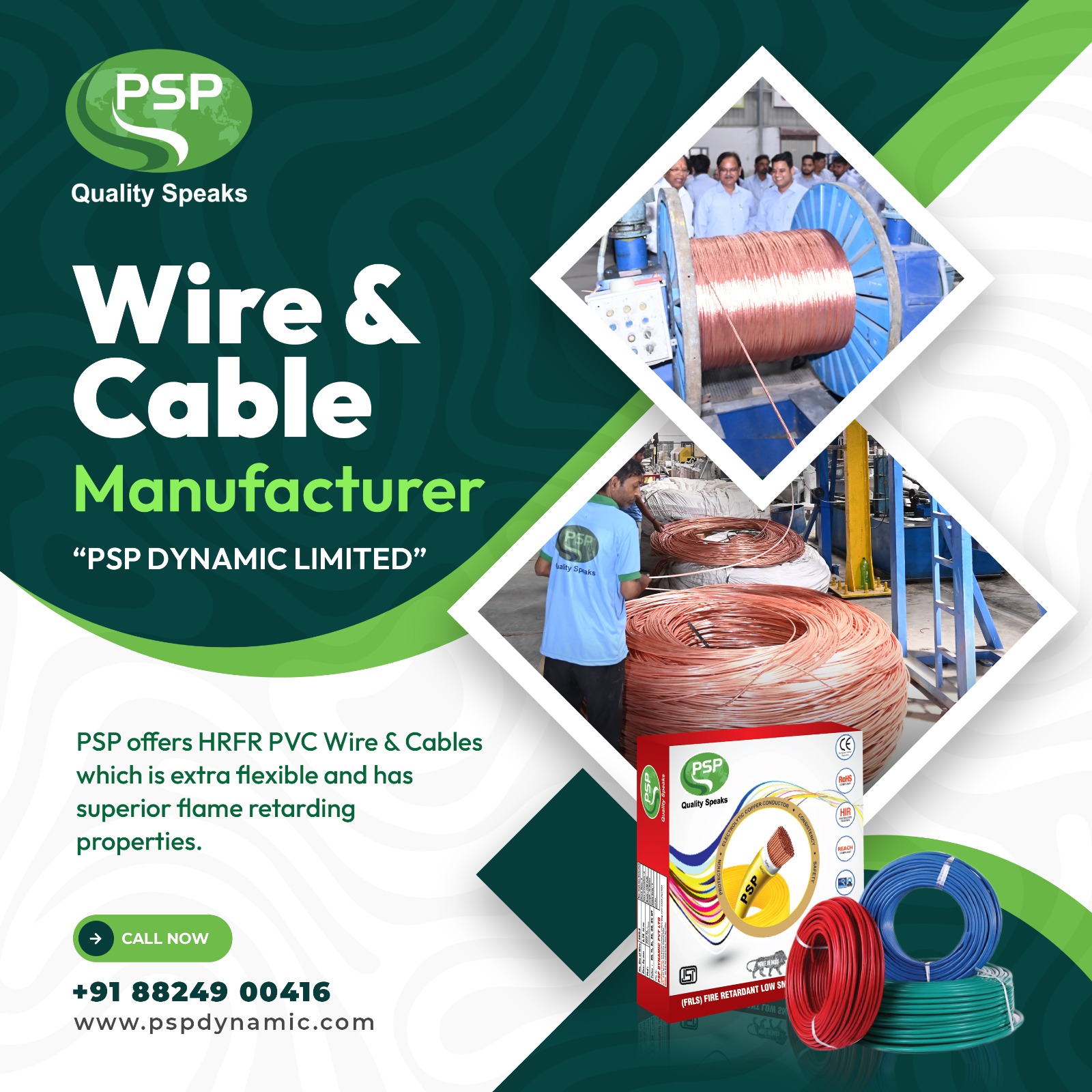

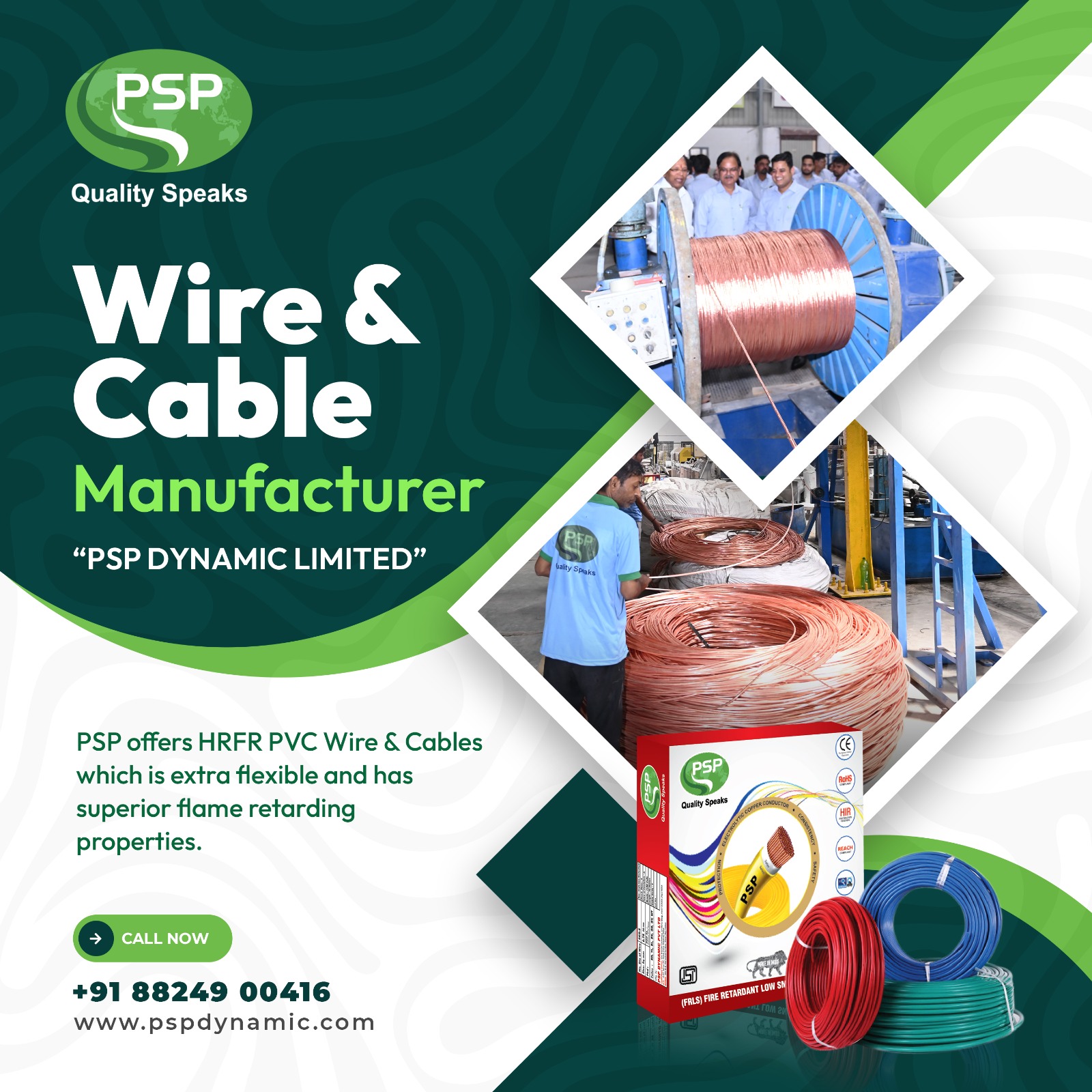

PSP Dynamic Limited, a leader in the electric wire manufacturing industry, is an example of the commitment to quality and innovation driving the sector forward in India.