The Electric Cable Industry in India | Innovations, Growth, and Market Dynamics

India's electric cable manufacturing sector plays a pivotal role in the country growing industrial landscape. With increasing demand for power, infrastructure development, and technological advancements, the need for reliable, safe, and high-performance electrical cables has never been greater. Electric cables are the lifeline of the modern power grid, enabling the transmission of electricity across cities, towns, and villages. These cables are integral to various sectors such as construction, telecommunications, energy, and transportation, making the electric cable industry a key contributor to the nation's economic growth.

In this blog, we will explore the electric cable industry in India, its significance, technological innovations, growth drivers, and the leading manufacturers driving the sector forward.

The Significance of Electric Cables in India Infrastructure Development

Electric cables serve as the medium for power transmission and distribution, which are essential for almost every sector residential, commercial, industrial, and more. From lighting up homes to powering factories, from facilitating communication to enabling transportation, cables are indispensable to modern life.

India is rapidly urbanizing, and with this growth comes an increased demand for electricity. In recent years, the country has made significant strides in enhancing its power infrastructure, with major investments in transmission and distribution systems. The government of India has rolled out several initiatives like "Power for All" and "24x7 Power Supply" to ensure that the entire country is connected to reliable electricity networks.

Additionally, as India seeks to become a manufacturing hub, there is a parallel push for infrastructure development, especially in the real estate, construction, and transportation sectors. In all of these areas, electric cables play a crucial role.

Types of Electric Cables Manufactured in India

The electric cable market in India is diverse, with a wide range of cables being manufactured to cater to the various needs of industries, homes, and commercial establishments. Here are some of the major types:

1. Low Voltage Cables

Low voltage cables are primarily used in residential and light commercial applications. These cables are designed to carry lower levels of electrical current (up to 1kV). Commonly used in domestic wiring, low voltage cables are often PVC-insulated to ensure safety and durability.

2. Medium Voltage Cables

Medium voltage cables operate at voltages ranging between 1kV and 33kV. These cables are used for electricity distribution in industrial and commercial applications, often connecting substations to power lines or industrial machines.

3. High Voltage Cables

High voltage cables are used for power transmission in the electricity grid, capable of handling voltages above 33kV. These cables are typically found in power plants, substations, and long-distance transmission lines.

4. Aerial Bundled Cables (ABC)

Aerial bundled cables are widely used in overhead distribution networks. The cables are bundled together to minimize the risks of short circuits or damage from external elements like weather. ABC cables are common in rural and semi-urban areas.

5. Flexible Cables

These cables are designed for high flexibility and are used in applications that require frequent movement of the cables, such as in machinery, robots, and automation systems. They are often found in industrial plants and manufacturing units.

6. Coaxial Cables

Coaxial cables are used for telecommunications and broadcasting applications. These cables are used to transmit data, video, and audio signals, and are essential for cable television networks, internet services, and telephone lines.

7. Control and Instrumentation Cables

Control and instrumentation cables are used in industries that require precise monitoring and control of electrical systems. These cables are found in automation systems, control panels, and machinery, ensuring smooth operation in industries such as power, oil and gas, and manufacturing.

Growth Drivers for the Electric Cable Industry in India

The electric cable manufacturing industry in India is experiencing rapid growth, driven by several key factors:

1. Government Initiatives and Policy Support

The Indian government has been actively supporting the power and infrastructure sectors with policies aimed at improving electricity generation, transmission, and distribution. Programs like "Make in India" have encouraged local manufacturing of cables, reducing dependence on imports. Additionally, the governmental focus on expanding rural electrification, upgrading the national grid, and promoting renewable energy sources is pushing up demand for electric cables.

2. Urbanization and Infrastructure Development

India's urban population is expanding rapidly, leading to an increase in demand for residential and commercial buildings, as well as industrial complexes. As new cities and towns emerge, there is a heightened demand for electrical infrastructure, including cables, to support housing, transportation, and communication networks.

With infrastructure projects such as metro systems, airports, roads, and bridges, the demand for high-performance cables is expected to grow significantly. Additionally, large-scale projects such as the Delhi-Mumbai Industrial Corridor (DMIC) and the Bharatmala Pariyojana are providing massive opportunities for cable manufacturers in the country.

3. Renewable Energy Transition

India is making significant strides toward a greener energy future. With ambitious targets for renewable energy capacity (e.g., 500 GW by 2030), the energy sector is shifting to solar, wind, and hydroelectric power generation. These renewable energy projects rely on advanced electrical cables for transmitting power from generation sites to the grid. As the country continues to invest in renewable energy, demand for specialized cables, such as solar cables and wind turbine cables, will rise.

4. Industrial Growth

India is positioning itself as a global manufacturing hub. The government's "Atmanirbhar Bharat" initiative, aimed at making India self-reliant, is a major push for industrial development, resulting in increased demand for electrical wiring and cabling solutions across sectors such as manufacturing, transportation, chemicals, and automotive.

5. Telecommunication Expansion

With the rollout of 4G and 5G networks, telecommunication infrastructure is undergoing a massive upgrade. The expansion of these networks requires the installation of high-quality coaxial cables, fiber optic cables, and other related products to ensure seamless connectivity.

Technological Innovations in the Electric Cable Industry

As the demand for power increases, the electric cable industry has witnessed several technological advancements aimed at improving the efficiency, durability, and safety of cables. Some of the key innovations include:

1. Enhanced Insulation Materials

The use of high-performance insulation materials such as cross-linked polyethylene (XLPE) has revolutionized the electric cable industry. XLPE cables offer higher temperature resistance, better mechanical properties, and improved safety compared to traditional PVC cables.

2. Smart Cables

With the advent of smart grids and IoT (Internet of Things), the electric cable industry is moving towards the development of smart cables that can monitor the flow of electricity, detect faults, and provide real-time data. These cables help in the efficient management of power and reduce downtime due to faults.

3. Fire-Resistant and Low Smoke Zero Halogen Cables (LSZH)

Safety is a critical concern when it comes to electrical installations. Cables that are fire-resistant, flame-retardant, and low smoke zero halogen (LSZH) are becoming increasingly popular, especially in commercial buildings, public spaces, and transport systems.

4. Fiber Optic Cables

Fiber optic cables have revolutionized the way data and communications are transmitted. These cables are capable of carrying huge amounts of data at high speeds with minimal loss, making them ideal for the rapidly expanding telecom and data transmission markets.

Leading Manufacturers in the Electric Cable Industry

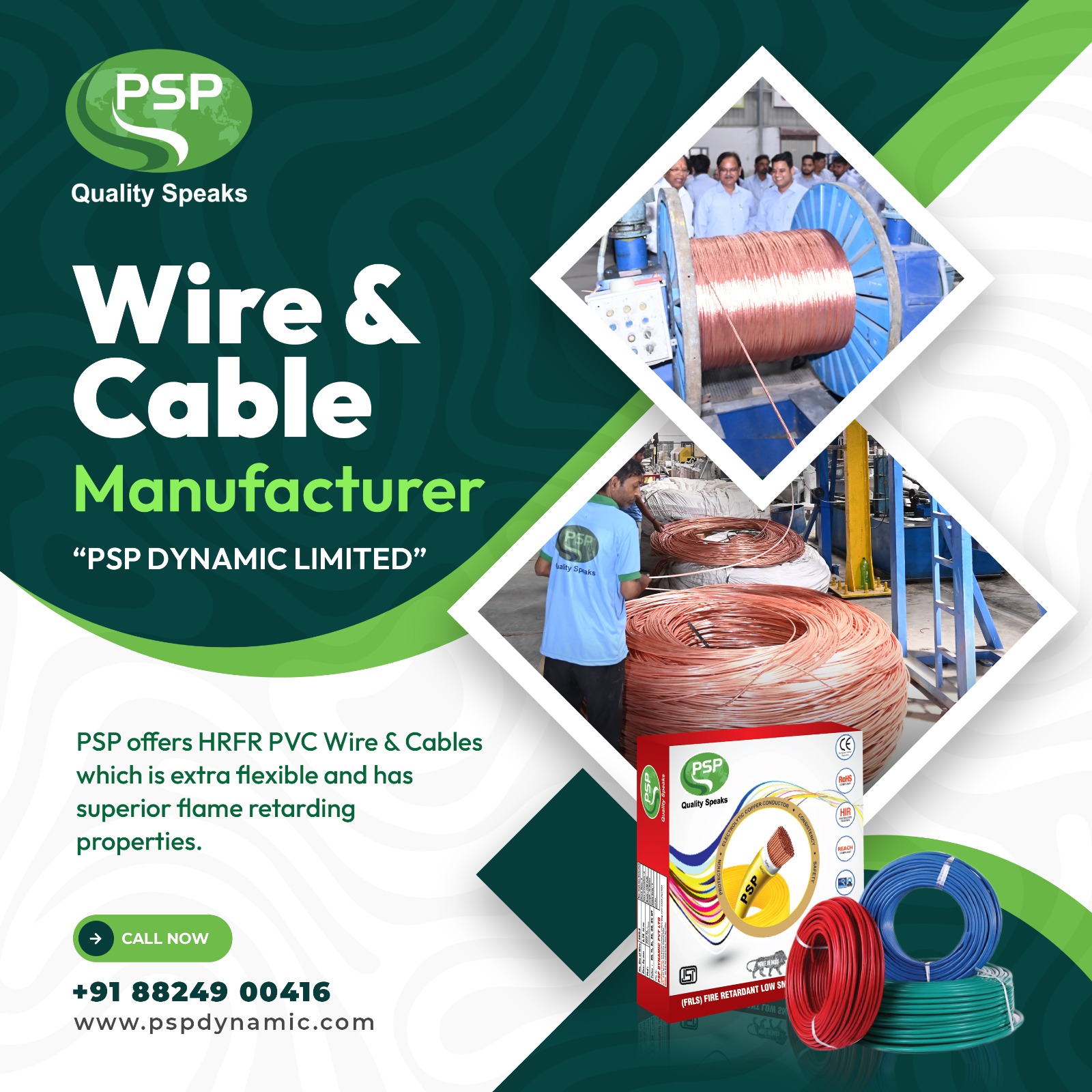

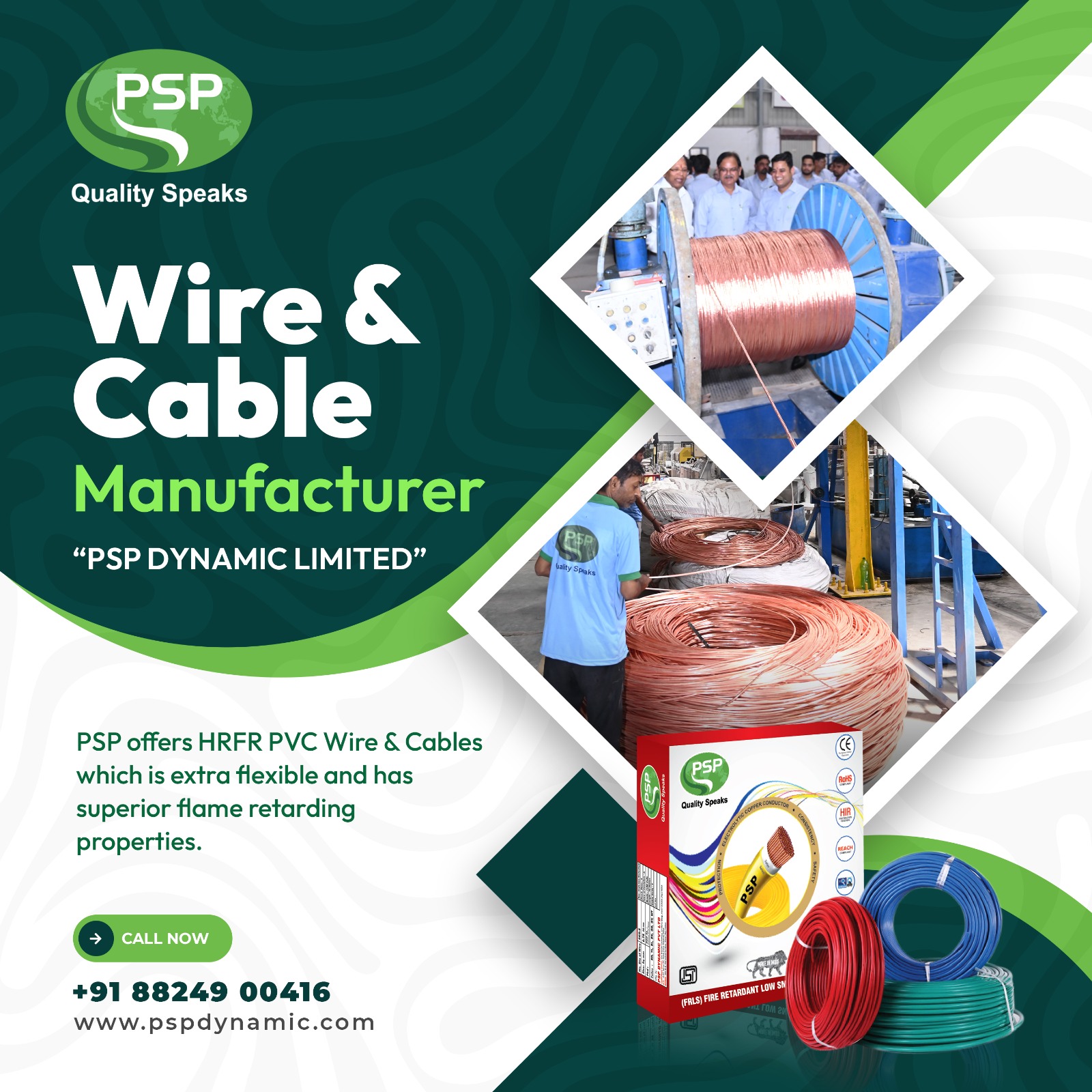

The electric cable market in India is highly competitive, with numerous domestic and international players. Manufacturers like PSP Dynamic Limited have been at the forefront of producing high-quality electrical cables that meet global standards. Companies in this space invest heavily in R&D to bring innovative products to the market, and they are continually striving to improve their product offerings, such as increasing the safety and efficiency of cables while reducing production costs.

Challenges in the Electric Cable Industry

Despite the opportunities, the electric cable industry in India faces several challenges:

- Raw Material Costs: Fluctuating prices of copper and aluminum, the primary materials used in cables, can significantly affect production costs and margins.

- Competition from Imports: While India has a robust manufacturing base, there is still heavy reliance on imported cables, particularly from China. Local manufacturers must contend with this competition while adhering to high standards of quality.

- Regulatory Compliance: As the industry moves towards more advanced technology and higher safety standards, manufacturers must navigate an increasingly complex regulatory environment.

Conclusion

The electric cable manufacturing in India is poised for substantial growth, driven by government initiatives, technological advancements, and rising demand from the infrastructure, industrial, and telecommunications sectors. With a wide array of applications and a steady push toward innovation, the industryâÂÂÂÂs future looks bright. However, to sustain growth, manufacturers must address challenges such as cost control, competition, and maintaining high-quality standards.

In this dynamic market, manufacturers that embrace new technologies and adapt to evolving industry trends will undoubtedly stay ahead of the curve. With consistent investments in research and development, and by focusing on quality and innovation, companies can continue to play a crucial role in shaping India's infrastructure and power distribution landscape for the future.