Thermocol Sheet Manufacturers in Ghaziabad: A Complete Guide

Thermocol sheets, also termed expanded polystyrene (EPS) sheets, turned out to be quintessential ingredients in different industries due to their flexibility, lightweight characteristics, and economical attributes. In Ghaziabad, a booming industrial hub in close proximity to Delhi, the demand for thermocol sheets has spiked considerably because of its blossoming manufacturing and building sector over the years. The applications of thermocol sheets can be found at varied levels of importance from packaging to insulation and even construction. This blog would cover a few basics regarding thermocol sheets, their manufacturing processes, and why Ghaziabad is emerging as a prime manufacturing location for thermocol sheets with regard to the developing requirements in the business.

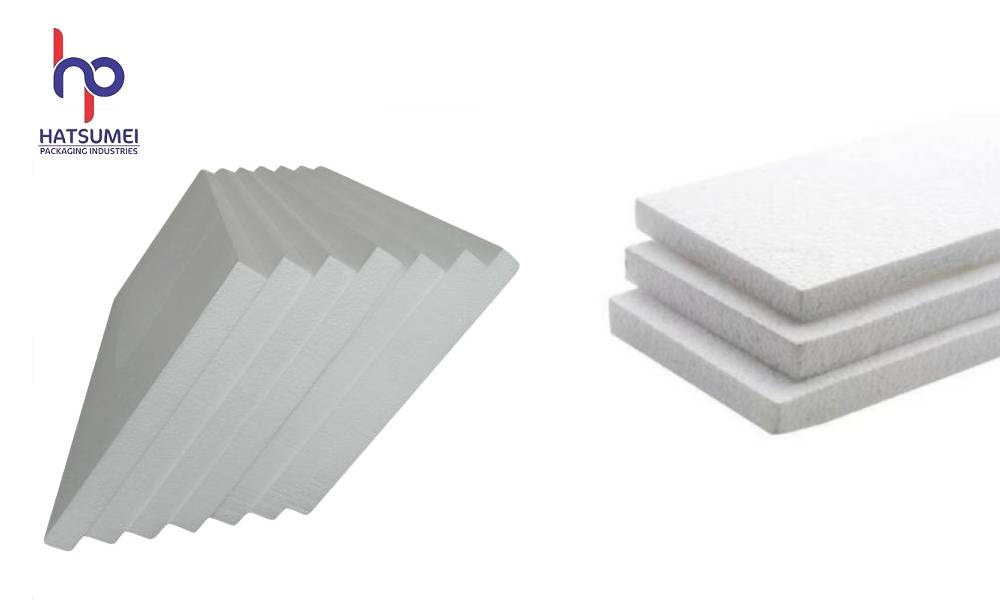

Understanding Thermocol Sheets

The thermocol sheets are formed from expanded polystyrene beads subjected to heat and pressure, which generate large and solid sheets. These sheets possess excellent insulation properties with very low thermal conductivity and moisture resistance. Their rigidity is combined with low weight, making them suitable for any possible use.

Thermocol sheets are maybe the cheapest insulating material, making them a very affordable option for any packaging, insulation, or even construction. It is recycled and reused in many cases, thus being an environmentally friendly resource.

Uses of Thermocol Sheets

Thermocol sheets are being used in a multitude of industries today. Some of the significant uses of thermocol sheets include:

1. Packaging Industry:

Thermocol sheets have become most commonly poured in the packaging products when they need a lightweight cover for protection. From electronic devices to fragile objects like glass and ceramics, these thermocol sheets help in safe delivery with shock absorption and cushioning. Its ability to resist water and moisture also augurs well for food packaging in containers for fruits, vegetables, and ready-eat meals.

2. Construction Industry:

Thermocol sheets are one of the most used materials in the construction industry today. They are primarily used to provide thermal insulation to walls, ceilings, and floors. Its lightweight property makes handling and installation easy, thereby resulting in an overall reduction in the weight of building buildings. Further, the thermal properties of thermocol sheets maintain the much-needed indoor temperature, thereby most often eliminating the need for excessive air conditioning or heating.

3. Automotive Industry:

The automobile industry also uses thermocol sheets for several purposes. These sheets are used in car interiors, packaging of auto parts, and for insulation. The lightweight property of the thermocol helps in the reduction of overall weight of the vehicle, thus improvement in fuel efficiency.

4. Thermal Insulation:

Used for thermal insulation in cold storage, thermocol sheets are wrapped quite tightly around refrigerators, and for those who wish to self-insulate their homes, they can also use these sheets.

5. Decoration and Crafts:

These thermocol sheets are most popularly used in the craft and event management industries. Artists and event planners use these sheets for making decorative items, making sculptures, and installations. Thermocol allows for limitless creativity in design because it is easy to cut and shape.

6. Sports and Leisure Products:

These consist of helmets, padding for sports equipment, and flotation devices-and there are many more-this section shows that most sports and leisure products are being safety insulated and buoyancy includes thermocol as being light and tough.

Manufacturing Process of Thermocol Sheets

To manufacture these thermocol sheets, an involved procedure has been developed to keep an eye on the precision level and skill vital for the high. Here's a brief look at the general manufacturing process:

1. Preparation of Polystyrene Beads:

The production of thermocol sheets is begun by preparing polystyrene beads. These beads are one of the major raw materials used for the manufacture of thermocol sheets. The beads are made from a polymerization process leading to small, solid beads of polystyrene.

2. Pre-Espanding the Beads:

Then, before processing them into thermocol sheets, steam is used to pre-expand the polystyrene beads. In the process of soaking, they absorb steam and expanded up to 40 times more than their original size. Thus comes about the final lightweight and structure endowed to the beads by this process to form thermocol sheets.

3. Mold the Expanded Beads:

Further, the expanded pre-beads are placed in a mold along with added steam, which blows up and helps links between these two beads. This uses a mold very carefully controlled in order to have very uniform density and thickness of the sheet.

4. Cool and Cut:

After molding, the sheets are cooled to room temperature. The sheets can then be cut to size and shape after being cooled, ready for various applications. Customization can also include specific cuts to the sheets for particular needs concerning thickness or length.

5. Quality Control and Packaging:

Quality control checks are then conducted to ensure that the final product conforms to the necessary standards before being shipped for sale. The tests carried out on thermocol sheets would include density, thickness, and insulation properties to ensure uniformity in production. After testing the quality of the sheets, they are now ready for packaging and forwarding to either clients or distributors.

Why Preferring to Choose Ghaziabad for Thermocol sheets?

Ghaziabad, Uttar Pradesh, is an industrial hub that has become a major manufacturing segment of thermocol sheets. There are many things that can be listed to point out the cause of emergence of Ghaziabad as the major

Why Ghaziabad for Thermocol Sheets?

Ghaziabad is an industrial town in Uttar Pradesh that has emerged as one of the significant manufacturing seats for thermocol sheets. The following reasons can be attributed to Ghaziabad being at the forefront of thermocol sheet fabrication:

1. Proximity to Large Markets:

Ghaziabad is strategically situated, with Delhi being one of the largest consumer markets near it. The closeness to the major transportation hubs such as highways, railways, and National and International airways puts an advantage for manufacturing and distribution. This enables manufacturers to cover the logistic distance rapidly and supply thermocol sheets to various industries in the country within a much shorter time.

2. Availability of Raw Materials:

Ghaziabad has several chemical and polymer industries, hence serving as a prime zone for producing raw materials considered essential for thermocol manufacturing. This area provides polystyrene beads, which are the primary raw materials for thermocol manufacture, ensuring continuous supply from the manufacturers operating in this region.

3. Skilled Labor Force:

Ghaziabad has a strong tradition of skilled and trained manpower in several manufacturing sectors. The availability of skilled and highly experienced labor helps thermocol sheet production standards attain the best quality.

4. Infrastructure and Industrial Development:

This city is endowed with good infrastructure, including industrial parks and manufacturing zones, which are conducive to large-scale production. Industrial policies in Ghaziabad are conducive to industrial development, thus making sure that growth in the manufacturing sector is achieved on a continuous basis.

5. Good Presence of Already Set-Up Manufacturers:

Many established manufacturers, including Hatsumei Packaging Industries, have set up shop in Ghaziabad and contributed to the reputation of the city as a place wheeling high-grade thermocol sheet production. The presence of such companies ensures products are manufactured with the latest technologies and processes.

Conclusion

Thermocol sheets are widely used in many industries because they are light, durable, and insulating. Demand for thermocol sheets in Ghaziabad has been increasing because of the strong industrial base as well as the strategic geographical location. The manufacturers of Ghaziabad, including Hatsumei Packaging Industries, are prominent in addressing the said demand, offering high-end products that serve many purposes.

As the industries grow, the importance of thermocol sheets in packaging, insulation, construction, and other activities will increase. The furtherance of the thermocol-sheet production business will see Ghaziabad remaining as a relevant player due to an even-more flourishing manufacturing sector along with-founded amenities. Ghaziabad is a location with many opportunities for sourcing high-quality thermocol sheets, whether for a dependable supplier or for engaging a manufacturer for your business.