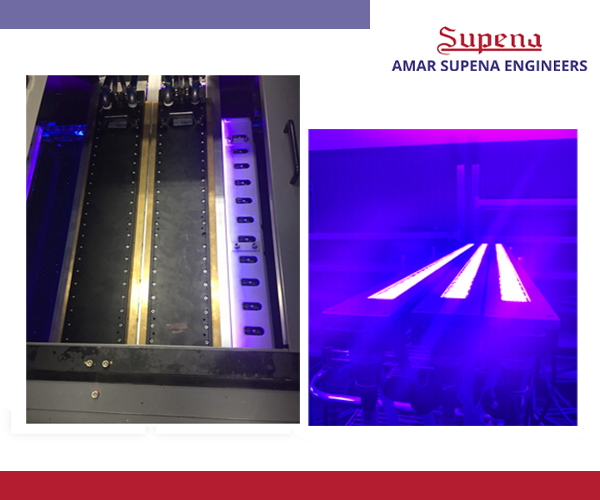

LED Curing Systems | The Future of Efficient and Sustainable Curing Technology

The manufacturing and printing industries are under constant pressure to improve production speeds, reduce energy consumption, and meet ever-stricter environmental regulations. One of the most exciting technological advancements in curing technology is the rise of LED curing systems. These systems are increasingly replacing traditional curing methods, including mercury vapor lamps, due to their superior efficiency, sustainability, and versatility. In this blog, we will explore what LED curing is, how it works, its benefits, and why companies like Amar Supena Engineers are at the forefront of offering LED curing solutions for various industrial applications.

What is LED Curing?

LED curing refers to the use of Light Emitting Diodes (LEDs) as a light source to initiate the curing process of coatings, inks, adhesives, and other materials. Unlike traditional curing methods that rely on ultraviolet (UV) lamps or heat, LED curing uses LEDs that emit UV light at specific wavelengths to cure or harden materials almost instantaneously.

LED curing systems are part of a broader trend toward more energy-efficient and environmentally friendly technologies. LED lamps offer distinct advantages over conventional mercury vapor lamps, particularly in industries where precision, energy consumption, and sustainability are critical.

The main difference between LED curing and traditional UV curing lies in the light source. Traditional UV curing systems use mercury vapor lamps, which emit a broad spectrum of UV light. In contrast, LED curing systems use solid-state technology and emit light in a narrow, precise spectrum. This precision allows for better control over the curing process, resulting in higher quality finishes and faster production cycles.

Key Components of an LED Curing System

An LED curing system typically consists of the following components:

LED Light Source: The heart of the LED curing system. These light sources emit UV light at a specific wavelength, typically in the UV-A range, which is ideal for curing a wide variety of materials.

Reflectors: Reflectors are used to direct and focus the UV light emitted by the LED lamps onto the material being cured. This maximizes the energy efficiency of the system.

Cooling System: LED lamps generate significantly less heat than traditional mercury vapor lamps, but they still require effective cooling to ensure optimal performance and long operational life.

Control Systems: These systems allow users to adjust and regulate the curing parameters, including light intensity, curing time, and wavelength. Modern LED curing systems may come with automated controls that ensure consistent performance and high-quality results.

Power Supply: LED curing systems require a reliable power source to operate the LEDs at the necessary intensity. The power supply is designed to ensure stable and consistent energy output to the LED lamps.

Advantages of LED Curing Systems

1. Energy Efficiency

One of the most significant benefits of LED curing systems is their energy efficiency. LED lamps consume considerably less power than traditional mercury vapor UV lamps, making them an ideal choice for businesses seeking to reduce operational costs and their carbon footprint. The solid-state technology of LED lights also means less wasted energy in the form of heat, making LED curing a more sustainable option.

Moreover, LED curing systems can operate at lower temperatures, which reduces the need for extensive cooling systems. This not only saves energy but also contributes to the longevity and reliability of the equipment.

2. Longer Lamp Life

LED curing systems offer a remarkable advantage in terms of lamp longevity. While traditional mercury vapor lamps have a lifespan of around 1,000â2,000 hours, LED lamps can last up to 20,000â25,000 hours, depending on usage and maintenance. This significant increase in lamp life reduces the frequency and cost of replacements, which is a major advantage for high-volume manufacturing environments.

Additionally, LED lamps are not affected by frequent on/off cycles, which can cause wear and tear on traditional UV lamps. This further enhances the reliability and cost-effectiveness of LED curing systems.

3. Faster Curing Times

LED curing systems are incredibly fast, with curing times often reduced to a fraction of what is required by traditional curing methods. LED curing systems can cure coatings, inks, and adhesives almost instantly upon exposure to UV light, speeding up production cycles and increasing throughput. This is particularly beneficial in high-speed applications like digital printing, packaging, and automotive manufacturing, where reducing downtime is essential for maintaining productivity.

4. Reduced Heat Emission

Unlike traditional UV curing systems that generate a significant amount of heat, LED curing systems emit very little heat. This is a key advantage in industries where heat-sensitive materials are involved. For example, in the printing industry, heat buildup can cause paper and other substrates to warp or deform, resulting in costly defects. LED curing helps mitigate this risk by maintaining a cooler curing environment.

Furthermore, reduced heat emissions allow LED curing systems to be used on a wider range of materials, including plastics, films, and delicate substrates that would otherwise be damaged by excessive heat.

5. Precise Wavelength Control

LED curing systems offer precise control over the UV light's wavelength. This is important because different materials cure best at specific UV wavelengths. With LED curing systems, users can select the optimal wavelength for their specific applications, ensuring better curing results and higher-quality finishes. The ability to tailor the light spectrum provides greater flexibility and accuracy, making LED curing systems ideal for specialized applications in industries such as electronics, automotive, and medical device manufacturing.

6. Eco-Friendly

LED curing systems are more environmentally friendly compared to traditional curing technologies. For one, they do not contain mercury, unlike mercury vapor UV lamps, which can pose environmental hazards when disposed of improperly. Additionally, the lower energy consumption of LED systems reduces overall greenhouse gas emissions, making them a more sustainable choice for businesses looking to reduce their environmental impact.

LED lamps also emit little to no UV-A or UV-B radiation outside of the specific wavelengths needed for curing, further reducing potential environmental and health risks.

Applications of LED Curing Systems

LED curing technology is incredibly versatile and is used in a wide range of applications across various industries. Some of the most common applications include:

1. Printing and Packaging

In the printing industry, LED curing has revolutionized the production of printed materials. UV inks cured by LED systems enable faster printing on a variety of substrates, including paper, plastic, and metal. These inks also offer improved durability and resistance to fading and scratching, making LED curing ideal for packaging, labels, and other printed materials that require a high-quality finish.

Moreover, LED curing's energy efficiency and faster curing times make it perfect for high-speed, high-volume printing applications.

2. Automotive Industry

LED curing systems are used for coatings, finishes, and adhesives in the automotive industry. The ability to cure coatings quickly and precisely leads to superior finishes and improved durability of automotive parts. LED curing is especially beneficial in applications such as wheel coatings, dashboards, trim, and exterior finishes, where high-quality, long-lasting coatings are crucial.

3. Electronics and Circuit Boards

In the electronics industry, LED curing is used to cure solder masks, adhesives, and coatings on printed circuit boards (PCBs). The precision of LED curing systems ensures that delicate electronic components are not damaged by excessive heat, while the fast curing time improves production efficiency.

LED curing is also ideal for bonding applications where quick and strong adhesive bonds are needed, such as in assembling components for smartphones, tablets, and other electronic devices.

4. Medical and Pharmaceutical Industries

LED curing technology is used in the medical and pharmaceutical industries for sterilization, bonding, and coating applications. For instance, LED-cured adhesives are used in medical device manufacturing, where strong, durable bonds are necessary, but heat-sensitive materials need to be protected. LED curing is also employed for coatings on medical devices to ensure sterility and improve the longevity of devices such as syringes, catheters, and surgical instruments.

5. Wood and Furniture

LED curing systems are used for finishing and coating wooden surfaces in the furniture and woodworking industries. The ability to apply durable, high-quality coatings to wood products quickly and efficiently makes LED curing systems a valuable tool for improving production efficiency and finish quality.

Why Choose Amar Supena Engineers for LED Curing Solutions?

Amar Supena Engineers is a leading provider of advanced LED curing systems that offer high performance, efficiency, and sustainability. Hereâs why businesses choose Amar Supena Engineers for their LED curing needs:

1. Expertise and Innovation

With years of experience in the curing industry, Amar Supena Engineers offers cutting-edge LED curing solutions tailored to meet the unique needs of various industries. Their team of experts ensures that each system is designed to provide optimal performance for your specific application.

2. Customization and Flexibility

Whether you need a small-scale curing system for a niche application or a large-scale, high-volume solution, Amar Supena Engineers provides customizable systems that can be tailored to your production requirements. Their systems are flexible and scalable, ensuring that you get the most effective solution for your needs.

3. Energy Efficiency and Sustainability

As an eco-conscious company, Amar Supena Engineers offers LED curing systems that are designed to be energy-efficient and environmentally friendly. Their systems help businesses reduce energy consumption, minimize waste, and lower their carbon footprint.

4. High-Quality Equipment and Support

Amar Supena Engineers is committed to providing high-quality LED curing systems that deliver consistent, reliable results. In addition to supplying advanced curing equipment, they offer comprehensive support, including installation, training, and maintenance, ensuring that your operations run smoothly.

Conclusion

LED curing systems are revolutionizing industries by offering faster curing times, higher-quality finishes, and energy efficiency. From printing and packaging to automotive and electronics, LED curing technology is reshaping the way products are made. By choosing Amar Supena Engineers for your LED curing needs.