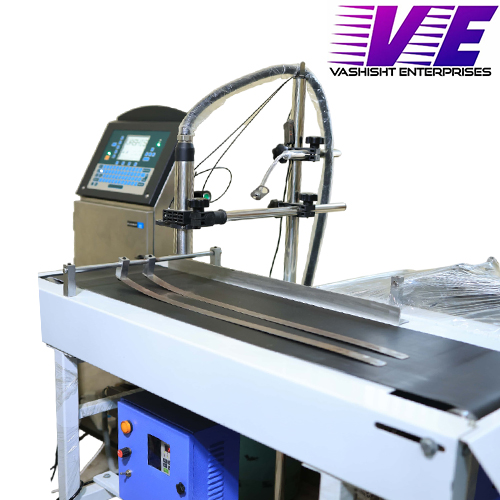

Conveyor Belts: The Backbone of Modern Industrial Efficiency in Delhi NCR

In the fast-paced and ever-evolving industrial world, operational efficiency is key to staying ahead of the competition. One of the most critical components in ensuring that industries remain productive and efficient is the conveyor belt. Whether in manufacturing, packaging, or logistics, conveyor belts play a central role in automating processes and facilitating smooth movement of goods from one point to another. Businesses in Delhi NCR, a dynamic industrial hub, rely heavily on conveyor belts to streamline their operations and improve productivity.

Conveyor Beltsare an essential part of many industries, and their importance has only grown in the age of automation. In this blog, we will explore what conveyor belts are, the various types available, their key features, and the significant benefits they offer businesses in Delhi NCR.

What is a Conveyor Belt?

A conveyor belt is a continuous loop of material used to transport items or materials from one location to another. It is typically powered by an electric motor or a drive system that moves the belt across rollers. Conveyor belts are used in a variety of industries to move products, raw materials, and finished goods through different stages of production, packaging, or distribution. They are an integral part of many production lines, allowing for faster and more efficient processes, reducing labor costs, and minimizing human error.

The simplicity, efficiency, and versatility of Conveyor Belts make them indispensable in modern industrial processes.

Types of Conveyor Belts

Conveyor Belts come in various designs and materials to suit different industrial needs. The following are some of the most common types:

1. Flat Belt Conveyors

Flat belt conveyors are among the most commonly used types of conveyor systems. These belts consist of a flat, flexible surface that is ideal for carrying lightweight materials such as packaged products, boxes, and small components. The simplicity of flat belt conveyors makes them suitable for a variety of applications across industries such as food processing, electronics manufacturing, and consumer goods packaging.

2. Modular Belt Conveyors

Modular belt conveyors consist of interlocking plastic modules that create a flexible and durable conveyor surface. They are often used in industries where flexibility, easy maintenance, and customization are required. For example, modular belts are frequently used in the food and beverage industry for the transportation of products that may require special handling, such as fragile or hot items.

3. Roller Conveyors

Roller conveyors use rollers instead of a continuous belt to move items. These systems are highly suitable for heavy-duty applications, where the conveyor needs to carry large and heavy loads. Roller conveyors are commonly used in warehouses, distribution centers, and in industries such as automotive manufacturing and logistics.

4. Inclined Belt Conveyors

Inclined conveyors are used to transport materials from one level to another. These are commonly found in industries like mining and recycling, where raw materials need to be moved from lower to higher elevations or vice versa. Inclined belt conveyors can be customized with varying angles to suit different needs.

5. Trough Belt Conveyors

Trough belt conveyors are designed with sides that prevent materials from spilling off the sides of the belt, making them ideal for bulk handling. These belts are often used in industries such as agriculture, mining, and recycling to carry materials like coal, grains, and ores.

6. Air Cushion Conveyors

These conveyors are designed to float above the ground on a cushion of air, providing smooth and noise-free operation. Air cushion conveyors are typically used for light and delicate products like electronics or glassware.

Key Features of Conveyor Belts

>Conveyor Belts come with various features that make them suitable for different industrial applications. Here are some key features that contribute to their functionality:

1. High Load Capacity

Conveyor belts are designed to carry a wide range of products, from light items to heavy, bulky materials. The load capacity varies depending on the design, material, and purpose of the belt. Some belts are capable of carrying several tons of materials per minute, making them ideal for heavy-duty industrial applications.

2. Durability

Conveyor Beltsare designed to be robust and capable of withstanding harsh operating environments. They are built to handle wear and tear, extreme temperatures, and even contact with chemicals or oils, depending on the material they are made from. The durability of a conveyor belt ensures that businesses can rely on these systems for long periods without the need for frequent maintenance.

3. Customizability

One of the standout features of Conveyor Belts is their ability to be customized to meet specific needs. Businesses can choose the type of belt material, design, and additional features such as belt width, speed, and incline to meet their production requirements. Custom conveyor systems can also be designed to fit unique spaces or accommodate specific production processes.

4. Efficiency and Speed

Conveyor belts are designed to operate at high speeds, allowing for continuous movement of materials, improving efficiency, and reducing the time it takes to complete a task. The high-speed capabilities of conveyor belts make them ideal for industries with high throughput demands, such as logistics and manufacturing.

5. Low Maintenance

Modern Conveyor Belts require minimal maintenance. Regular cleaning, lubrication of moving parts, and occasional inspections are typically all that is needed to ensure the system continues to run smoothly. This low-maintenance nature contributes to their cost-effectiveness and ease of use.

6. Versatility

Conveyor belts are incredibly versatile, suitable for a wide variety of materials and industries. From lightweight consumer goods to heavy industrial materials, conveyor belts can be tailored to meet the unique requirements of different industries.

Benefits of Conveyor Belts

For businesses in Delhi NCR, investing in conveyor belts conveyor belts offers numerous advantages that help improve production processes, reduce labor costs, and increase overall efficiency.

1. Increased Efficiency

Conveyor belts can drastically increase operational efficiency by automating the movement of materials and products. This reduces the need for manual labor, speeds up production, and allows for continuous operation without interruption. Whether you are in manufacturing, packaging, or warehousing, conveyor belts ensure smooth and efficient movement of goods.

2. Cost Savings

While the initial investment in conveyor systems may be significant, businesses in Delhi NCR experience significant cost savings over time. The automation of material handling processes reduces labor costs and minimizes the risk of human errors. Furthermore, conveyor belts have long lifespans, and their low maintenance costs contribute to overall savings.

3. Improved Workplace Safety

Using conveyor belts in industrial environments reduces the risk of workplace injuries caused by manual handling of materials. Conveyor systems eliminate the need for workers to lift, carry, or push heavy loads, reducing the likelihood of repetitive strain injuries and accidents on the factory floor. Furthermore, the automated nature of conveyor belts ensures that workers can focus on higher-value tasks.

4. Space Efficiency

Conveyor belts allow for the efficient use of space in industrial environments. With their ability to move products vertically or horizontally, businesses can optimize their floor layouts and streamline workflows. Conveyor belts can be designed to fit into tight spaces, maximizing storage and production areas.

5. High Throughput

For industries like logistics, where the volume of goods being processed is high, conveyor belts can handle large volumes of items with ease. The high-speed capabilities of conveyor systems ensure that goods are moved efficiently without bottlenecks, leading to faster processing times and increased throughput.

6. Flexibility for Different Industries

Conveyor belts are used across a wide range of industries, including food and beverage, pharmaceuticals, automotive, packaging, and more. Their versatility allows businesses in Delhi NCR to choose the most suitable conveyor system for their specific production requirements. Whether you are handling small parts or large bulk materials, there is a conveyor belt system that fits your needs.

Applications of Conveyor Belts

Conveyor belts have a wide range of applications across various industries. Here are some key industries where conveyor belts are commonly used:

1. Food and Beverage Industry

In the food and beverage industry,conveyor belts are essential for transporting raw ingredients, processed products, and packaging materials. Conveyor belts help streamline production lines, increase efficiency, and reduce contamination risks in food processing facilities.

2. Manufacturing and Assembly

Conveyor belts are widely used in manufacturing plants for transporting components, assemblies, and finished products. They improve efficiency and ensure that products move seamlessly through different stages of production.

3. Warehousing and Distribution

In warehousing and logistics, conveyor belts are crucial for efficiently moving products to and from storage areas. Automated conveyor systems speed up the sorting and packaging processes, making it easier to fulfill customer orders in a timely manner.

4. Pharmaceutical Industry

In the pharmaceutical industry, conveyor belts are used to transport medicines and packaging materials while maintaining cleanliness and minimizing contamination risks. Conveyor systems in the pharmaceutical sector are often designed to meet stringent regulatory standards.

Conclusion

Conveyor belts are vital to the modern industrial landscape, offering businesses in Delhi NCR a versatile and efficient solution for material handling. From enhancing productivity to reducing operational costs, conveyor belts play a crucial role in improving industrial processes across various sectors. Whether you are in food processing, logistics, or manufacturing, investing in high-quality conveyor belt systems is essential for streamlining operations and staying competitive in today fast-paced business environment. If you're looking for reliable and innovative conveyor belt systems, a reputable manufacturer can help you find the perfect solution for your needs.