In aluminium foundries and casting units, achieving clean, defect-free molten metal is critical for consistent quality and performance. Degasser for aluminium plays a vital role in removing dissolved hydrogen, non-metallic inclusions, and unwanted gases from molten aluminium. Jagannath Company stands among the top manufacturers and suppliers of aluminium degassers in India, offering reliable, high-performance solutions for both domestic and international markets.

With growing demand from automotive, aerospace, electrical, construction, and engineering industries, aluminium degassing has become an essential process. Jagannath Company provides advanced degasser solutions designed to improve casting integrity, reduce porosity, and enhance overall mechanical properties of aluminium alloys.

What Is a Degasser for Aluminium?

A degasser for aluminium is a specialized product or system used during the melting process to remove hydrogen gas and impurities dissolved in molten aluminium. Hydrogen is the primary cause of porosity in aluminium castings, leading to weak structures, surface defects, and rejection of finished components.

Why Degassing Is Essential in Aluminium Casting

Molten aluminium easily absorbs hydrogen from moisture, fluxes, and the surrounding atmosphere. If not removed before casting, this hydrogen forms gas pockets during solidification. Proper degassing ensures clean metal, smoother surface finish, higher strength, and improved machinability.

Key Problems Solved by Aluminium Degassers

Degassers help eliminate gas porosity, oxide inclusions, internal voids, and surface pinholes, resulting in higher-quality aluminium products with reduced scrap rates.

Types of Degasser for Aluminium Used in India

Jagannath Company offers different types of aluminium degassers suitable for small foundries as well as large-scale industrial operations. Selecting the right degasser depends on alloy type, furnace size, and production volume.

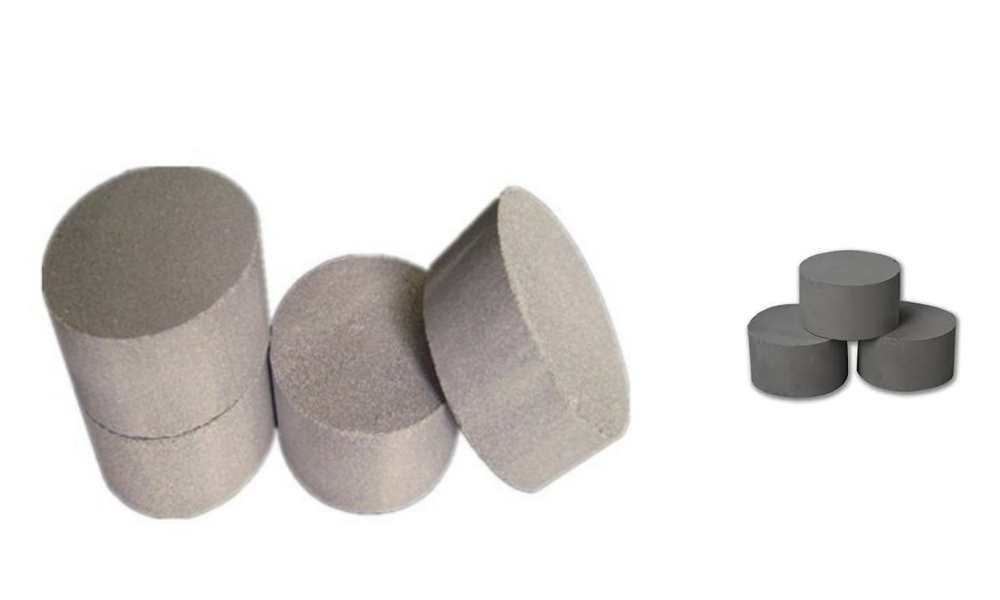

Tablet and Powder Degasser

Tablet and powder degassers are widely used in Indian aluminium foundries due to their ease of application and cost-effectiveness. They release active gases that bind with hydrogen and impurities, allowing them to escape from the molten metal.

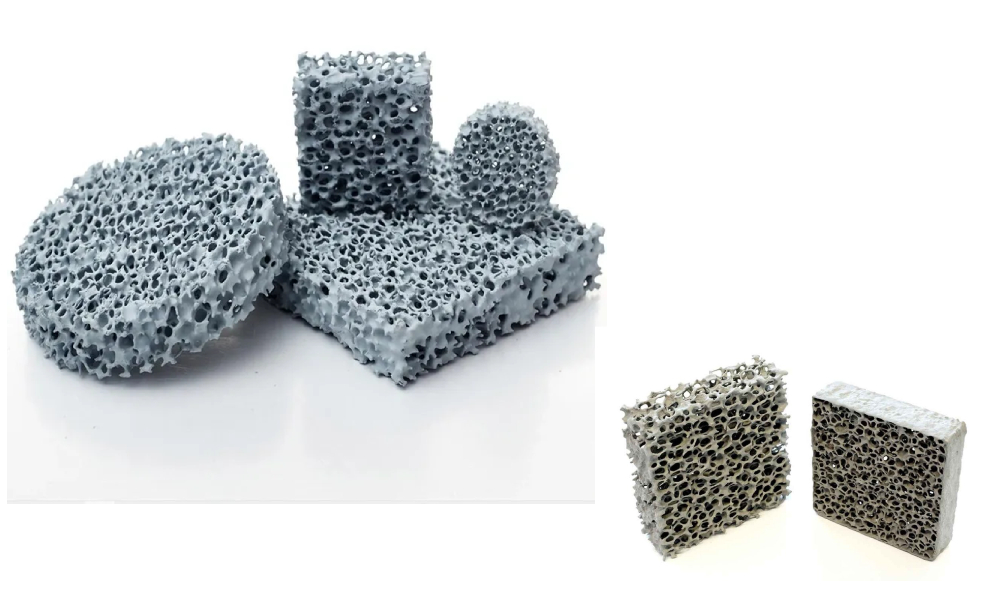

Rotary Degassing Systems

Rotary degassing is considered one of the best degassing methods for aluminium. It uses an inert gas, such as nitrogen or argon, injected through a rotating impeller to efficiently remove hydrogen and inclusions.

Flux-Based Degassers

Flux degassers combine cleaning and degassing action, helping remove oxides while improving metal cleanliness. These are suitable for specific aluminium alloy grades.

Best Degasser for Aluminium – Why Jagannath Company

Jagannath Company is recognized as a trusted name in aluminium foundry chemicals and degassing solutions in India. Our products are developed with a focus on performance consistency, safety, and ease of use.

High Degassing Efficiency

Our aluminium degassers effectively reduce hydrogen levels, resulting in improved density index and reduced porosity in castings.

Improved Casting Quality

Using the best degasser for aluminium leads to smoother surface finish, enhanced mechanical strength, and superior dimensional accuracy.

Reduced Scrap and Rejection Rates

Proper degassing significantly lowers casting defects, saving cost and improving overall production efficiency.

Compatibility with Various Aluminium Alloys

Our degassers are suitable for primary aluminium, secondary aluminium, and a wide range of aluminium alloy grades.

Applications of Aluminium Degasser

Degassers manufactured by Jagannath Company are used across multiple industries that rely on high-quality aluminium castings.

Automotive Components

Engine blocks, cylinder heads, wheels, and transmission parts require defect-free aluminium, making degassing essential.

Electrical and Power Industry

Busbars, conductors, and aluminium electrical components depend on clean metal for conductivity and durability.

Construction and Infrastructure

Aluminium profiles, panels, and structural components benefit from degassing to ensure strength and surface quality.

General Engineering and OEM Casting Units

Precision cast parts for machinery and equipment demand reliable degassing for consistent performance.

Degasser for Aluminium in India – Growing Market Demand

India’s aluminium industry is rapidly expanding due to infrastructure growth, automotive manufacturing, and export-driven production. As a result, demand for high-quality aluminium degassers is increasing across foundries and OEM suppliers.

Domestic Market Growth

Indian foundries are upgrading to advanced degassing solutions to meet global quality standards and reduce internal defects.

International Export Demand

Degassers manufactured in India are exported to the Middle East, Africa, Southeast Asia, and Europe, where Indian manufacturers are valued for quality and cost efficiency.

SEO Visibility and High-Intent Keywords

From an SEO perspective, aluminium degasser products attract strong B2B search intent. Buyers actively search for reliable manufacturers, best degassing solutions, and export-ready suppliers.

High-Performing SEO Keywords

Keywords such as “degasser for aluminium in India,” “best aluminium degasser,” “aluminium degassing manufacturer,” “aluminium degassing tablet supplier,” and “industrial aluminium degasser” generate consistent impressions and qualified traffic.

India-Focused and Global SEO Reach

Search demand is particularly strong in India, UAE, Saudi Arabia, Iraq, Bangladesh, and African industrial markets, making aluminium degassers a high-conversion SEO product.

Why Jagannath Company Is a Trusted Aluminium Degasser Manufacturer

Jagannath Company combines industry experience, technical expertise, and customer-centric manufacturing to deliver dependable degassing solutions.

Strict Quality Control

Each batch is manufactured under controlled conditions to ensure consistent performance and safety.

Bulk Supply and Custom Solutions

We support bulk orders and customized formulations based on alloy type and furnace conditions.

Technical Support and Industry Knowledge

Our team provides guidance on degassing practices to help foundries achieve optimal results.

Conclusion

Degasser for aluminium is a critical component in producing high-quality aluminium castings. As one of the top aluminium degasser manufacturers in India, Jagannath Company offers some of the best degassing solutions trusted by foundries and industrial users worldwide. With proven performance, growing global demand, and strong SEO visibility, aluminium degassers continue to be a key product for modern aluminium manufacturing.